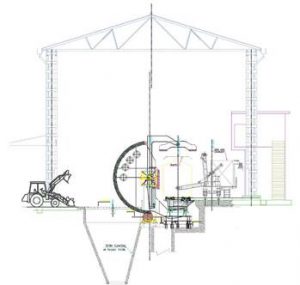

Prior to “Mission Electrification”, diesel locos were operating for unloading the rake in Wagon Tippler area based on which the Wagon Tippler was designed along with Side Arm Charger for onward movement of rake to loading platform to unload the material. Besides the above, an engine escape line was also connected to tippling line facilitating the onward of empty.

Considering presence scenario “Mission Electrification”, in response to the directives of Member Railway Board to reduce the dependency on the diesel fuel and also the directives of Member traction for electrification of tippler area, TRAINANCE has proposed for adoption of Retractable Rigid Catenary system to several Clients complying their requirement. TRAINANCE has also proposed necessary modification suiting the equipment installed and the plant layout of site.

ADVANTAGES

CIN – U5303DL2021PTC383632